Breffni Air Unltd have the capabilities to design bespoke engineered products specific to particular processes and client needs. We have an understanding of the client’s specific requirements and gaps in the supply chain to which we can offer innovative solutions.

This gain may be driven by cost, quality or schedule to which we can offer an incentive.

To date, we have successfully designed flow control dampers which have been embraced by our client and white-papered for use and sole supplier.

The engineering process involves:

- Client consultation.

- Initial design prototype.

- Prototype construction.

- Prototype operation modelling and simulation.

- Improvement scheduling and validation.

- Final design consultation with the client.

- Third party testing and accreditation.

- Quality control system and implementation.

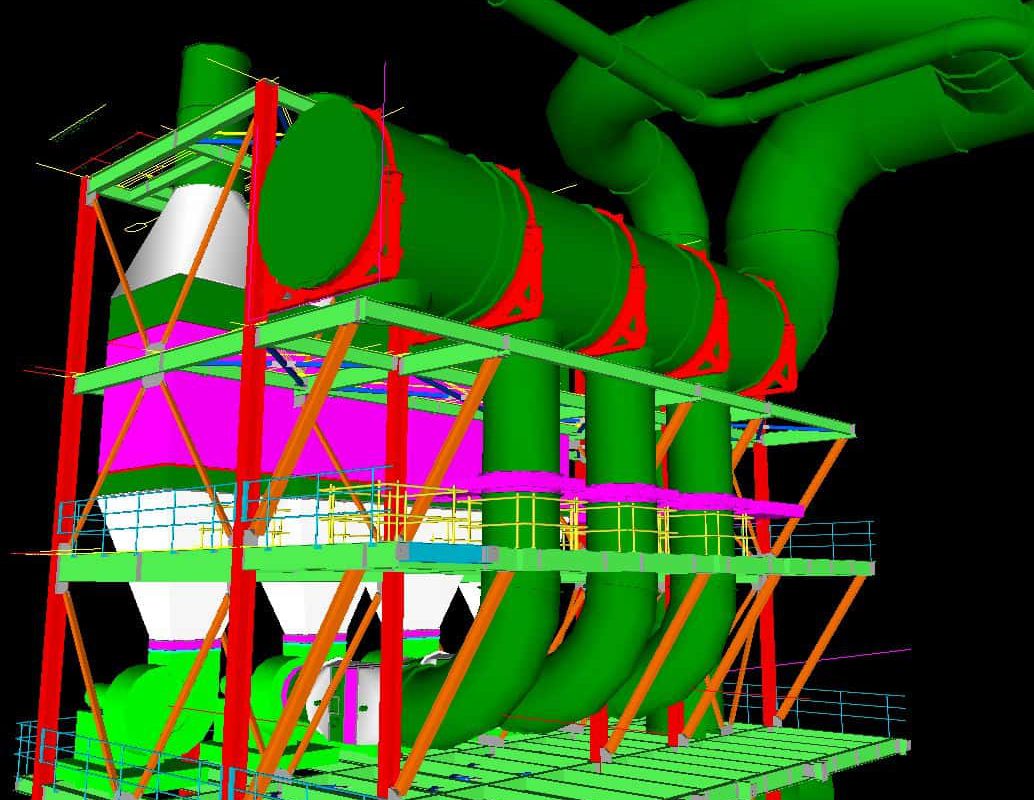

The engineering process is driven by a 3D CAD development and virtual motion simulation prior to fabrication. This enables fast improvements & modifications to be made. The structural validation, kinematic motion testing and tolerance stack analysis within the software provide accurate information prior to incurring material costs on prototypes thus making us more competitive.